Aerospace Workbenches

Aerospace operations demand workstations that can adapt to a wide spectrum of highly specialized tasks — from delicate avionics assembly requiring ESD protection to large-scale component fabrication that calls for extreme load capacities, custom fixtures, and integration with conveyors or material-handling equipment. Our aerospace workbenches are engineered for precision, durability, modularity, and long-term flexibility, ensuring your team has the right workspace configuration for everything from prototyping and inspection to full-scale production and MRO environments.

Looking for the right aerospace workbench? Our team can help you design an exact-fit solution.

Why Aerospace Workbenches Matter

Aerospace facilities—whether building aircraft fuselages, avionics assemblies, satellite components, or ground support tooling—require workstations that combine structural strength, flexibility, and precision

- Precision & Accuracy: Support component assembly without vibration, surface deflection, or instability.

- Heavy-Duty Load Capacity: Handle large assemblies, tooling, and machinery with robust frames and load-rated surfaces.

- Customization: Aerospace tasks vary widely — from wire harness assembly to engine maintenance — making modular, tailored workstations essential.

- Operator Safety & Comfort: Ergonomics reduce fatigue and help maintain consistent quality in high-precision tasks.

- ESD & Component Protection: Electrostatic discharge (ESD) safe surfaces protect sensitive avionics and aerospace electronics.

Recommended Aerospace Workbench Solutions: Built for Precision, Modularity & Heavy - Duty Performance

Here are the key product lines from Workbenches.com that best suit aerospace facilities — from prototyping through full-scale production:

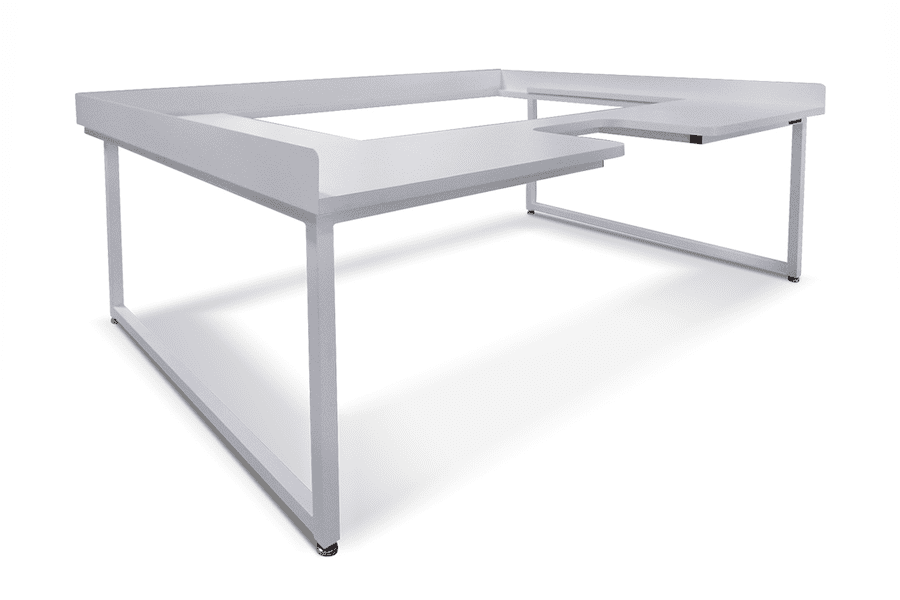

Personalized Workbenches

Custom configurations tailored for engine assembly stations, large fixture integration, part staging, or bespoke aerospace workflows.

Upperdeck Workbench

Enhanced ergonomic workbenches with overhead storage and integrated lighting — perfect for repetitive assembly and precision tasks.

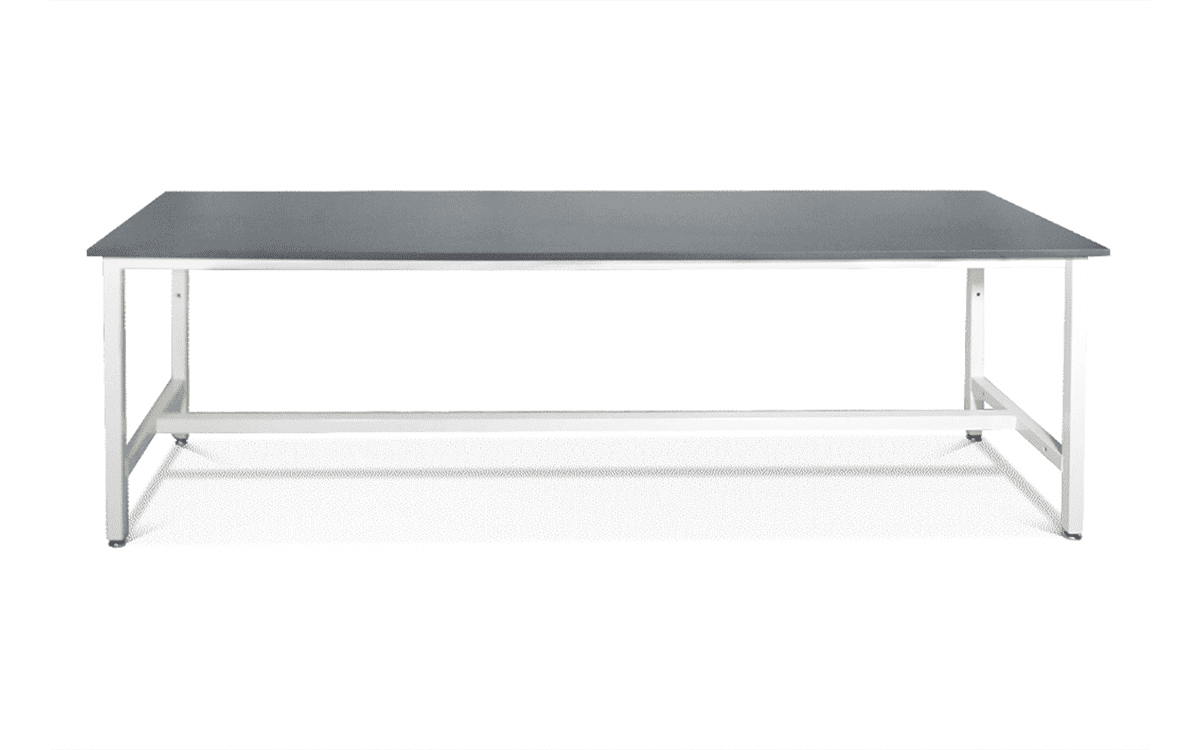

Corebench

Modular workbench platform ideal for wire harness assembly, inspection, layout, and light-to-medium industrial aerospace tasks.

Utility Workbench

Durable solution for heavy tooling stations, maintenance bays, and fabrication areas with optional accessories.

Industrial Storage Racks

Heavy-duty racks for storing aerospace components, tooling, and fixtures. Ideal for organized part staging and efficient production workflows

Services Lab Bench

Clean, utility-ready benches suited for avionics labs, testing cells, and component calibration areas.

Key Features of Aerospace Workbenches

From heavy-duty fabrication to delicate avionics work, aerospace operations require workbenches engineered for both performance and adaptability. These features highlight what sets aerospace-ready workstations apart.

- Heavy-Duty Frames & Surfaces – Welded steel or reinforced tubular frames with durable steel, stainless steel, orchemical-resistant worksurfaces built for long service life.

- Custom Work Surface Options – Configure benches with cut-outs, fixtures, tooling zones, integrated power, lighting, and tool mounts for aerospace-specific workflows.

- Ergonomic & Adjustable Workstations – Height-adjustable designs with integrated storage and accessory mounting support comfortable, lean, and efficient work.

- ESD-Safe & Clean Environment Compatibility – ESD-protected surfaces and grounding ensure electronic component safety; cleanroom-compatible options support controlled environments.

Typical Aerospace Furniture Use Cases

Aircraft Assembly & Component Fabrication

Workstations designed for stable, repeatable assembly of complex aerospace components with integrated fixtures and cut - outs.

Avionics & Electronics Work Cells

ESD - protected work benches for sensitive electronics assembly and test stations.

Maintenance, Repair & Overhaul (MRO) Operations

Heavy - duty benches and carts enable mechanics to disassemble, inspect, and repair engines, landing gear, and structural elements.

Inspection & Quality Control Stations

Ergonomic, vibration - controlled work areas optimize measurement accuracy and reduce fatigue in critical inspection roles.

Customization Options& Aerospace WorkbenchFAQs

Whether you’re setting up aproduction line, avionics lab, or maintenance facility, we can help you design asolution that delivers precision, strength, and workflow optimization.

- What materials are best for aerospace workbench surfaces?

Stainless steel, chemical-resistant epoxy, or industrial-grade laminate surfaces provide the durability and cleanliness aerospace tasks require. - Can aerospace workbenches integrate with conveyors or material-handling systems?

Yes—workbenches can be engineered to align with conveyor lines, flow racks, and automated material-handling equipment to support efficient, repeatable aerospace production workflows. - Do I need ESD-safe surfaces for aerospace applications?

If your team handles avionics, sensors, electronic assemblies, or diagnostic equipment, ESD-safe worksurfaces and grounding systems are strongly recommended to prevent static-related component damage. - How customizable are aerospace workbenches?

Very—benches can be configured with cut-outs, fixtures, power integration, lighting, shelving, tool rails, heavy-duty frames, and modular accessories designed around your exact tasks and part sizes. - Why should aerospace manufacturers work with Workbenches.com?

Our team has hands-on experience supporting many of the major aerospace companies, giving us a deep understanding of complex applications, industry standards, and workflow requirements—ensuring your workstation is engineered right the first time. - Can you help me design a workstation for a unique or complex aerospaceprocess?

Absolutely—whether you’re setting up an avionics cell, composite repair area inspection zone, or engine assembly station, our specialists can develop a tailored solution built around your specific tasks, tools, and performance requirements.

Need help configuring the right setup? Our specialists can guide you through all customization options.

How to Choose the Right Aerospace Workbench

When selecting aerospace-ready workstations, consider:

- Task Requirements – Do tasks require precision alignment, heavy lifting, or ESD control?

- Operator Ergonomics – Adjustable height or sit-stand configurations support worker health and productivity.

- Workflow Integration – Configurable layouts and modular accessories adapt to evolving aerospace manufacturing processes.

- Load & Durability Needs – Heavy-duty frames and reinforced surfaces ensure longevity under high usage.