Electronics Assembly Workbenches

Modern electronics assembly requires workstations that combine ESD protection, ergonomic design, smart storage, and workflow optimization to support tasks from component insertion and soldering to inspection and testing. Our electronics assembly workbenches are built with integrated storage solutions, bin rails, pegboards, tool organization systems, monitor mounting, and customization options to enhance productivity and protect sensitive components throughout the assembly process.

Looking for a workstation tailored to your electronics assembly line or lab? Our specialists can help you configure the right solution.

Why Electronics Assembly Workbenches Matter

Electronics assembly environments bring together high-speed production, sensitive components, and detailed task workflows that rely on efficient access to tools, parts, and testing equipment. Purpose-built electronics assembly workbenches help:

- Protect sensitive electronics with ESD-safe worksurfaces and grounding

- Organize parts and tools with bin rails, pegboards, and racks

- Streamline workflows with integrated storage and layout planning

- Enhance operator ergonomics for prolonged focus and reduced fatigue

- Support testing and inspection with monitor systems and utility integration

- Scale as production grows through modular and adaptable configurations

Recommended Electronics Assembly Workbench Solutions: Engineered for ESD Safety, Ergonomics & Workflow Efficiency

These Workbenches.com solutions support electronics assembly, testing, inspection, and kitting workflows. ESD-safe configurations are available where static control is required.

ESD Workbench

ESD-safe configuration of our CoreBench or UpperDeck platforms, equipped with a static-dissipative worksurface and grounding options to protect sensitive components.

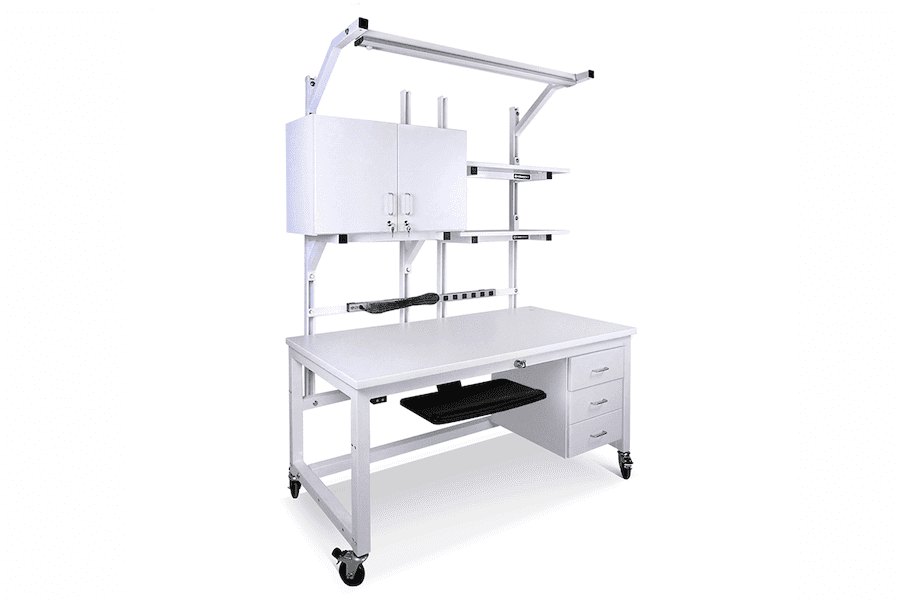

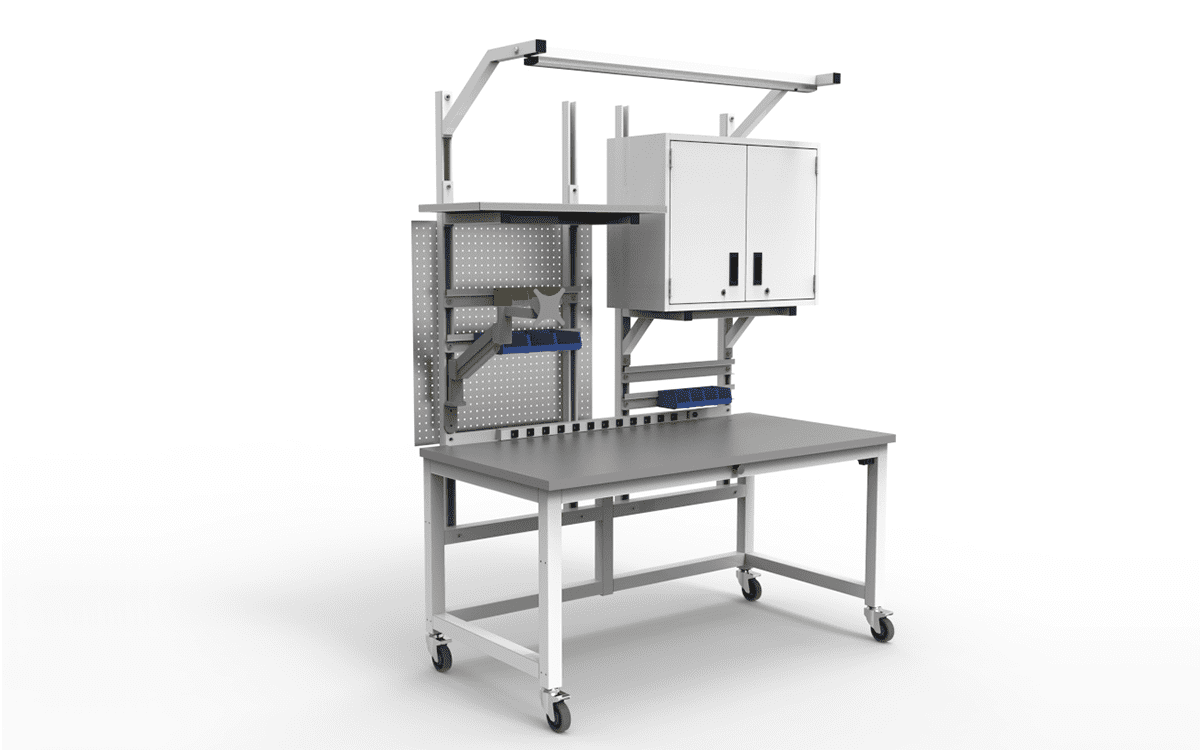

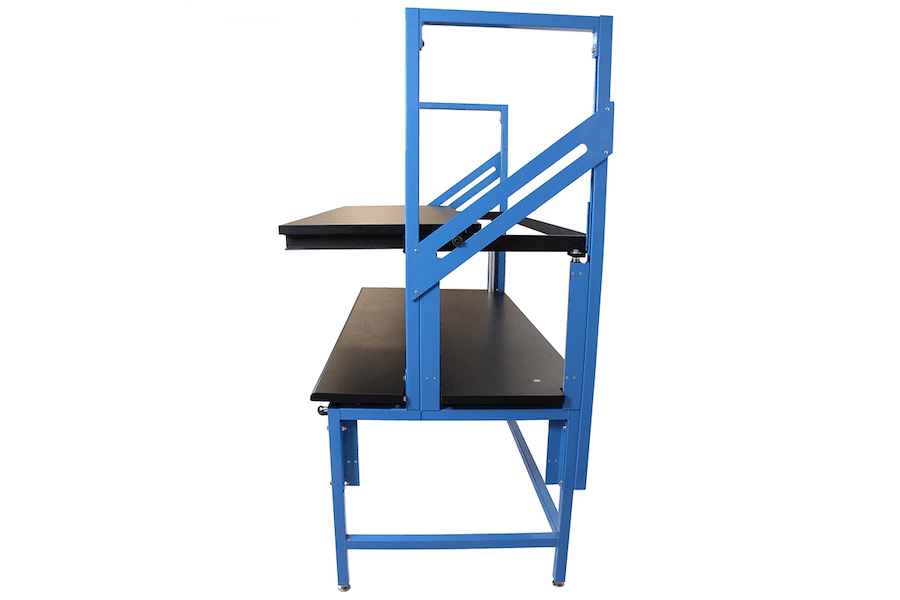

UpperDeck Workbench

Ergonomic workstation with overhead storage, lighting, and accessory support — well-suited for inspection, soldering, and precision assembly. ESD-safe surface options available.

CoreBench

Modular workbench platform ideal for electronics assembly, subassembly, and kitting tasks. Available with ESD-safe worksurfaces and grounding options for static-sensitive components.

Lab Carts

Mobile, ESD-compatible carts for moving tools, components, test equipment, and assemblies between workstations, production lines, and inspection areas.

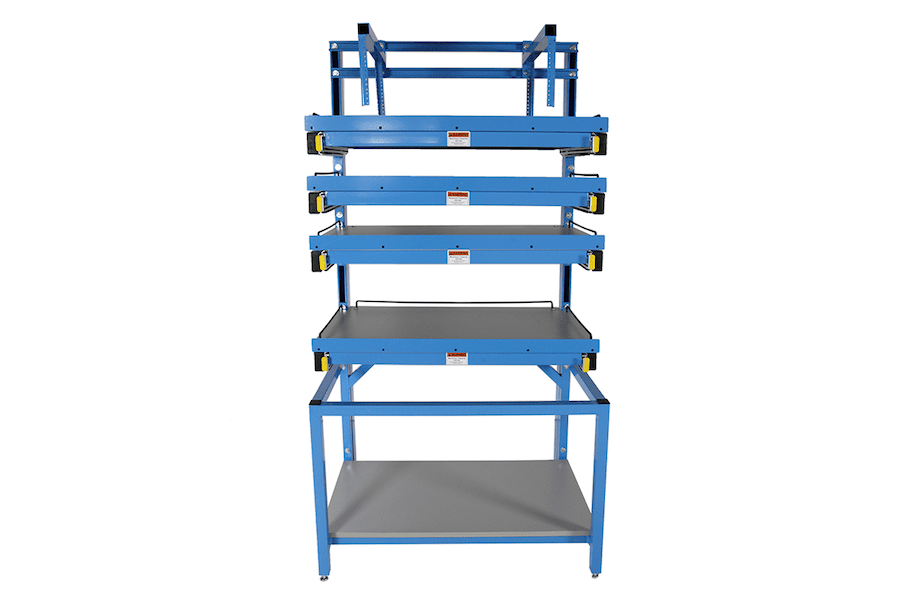

Industrial Storage Racks

Powder-coated or ESD-compatible rack systems for organizing components, reels, kits, and tooling near assembly lines or support zones.

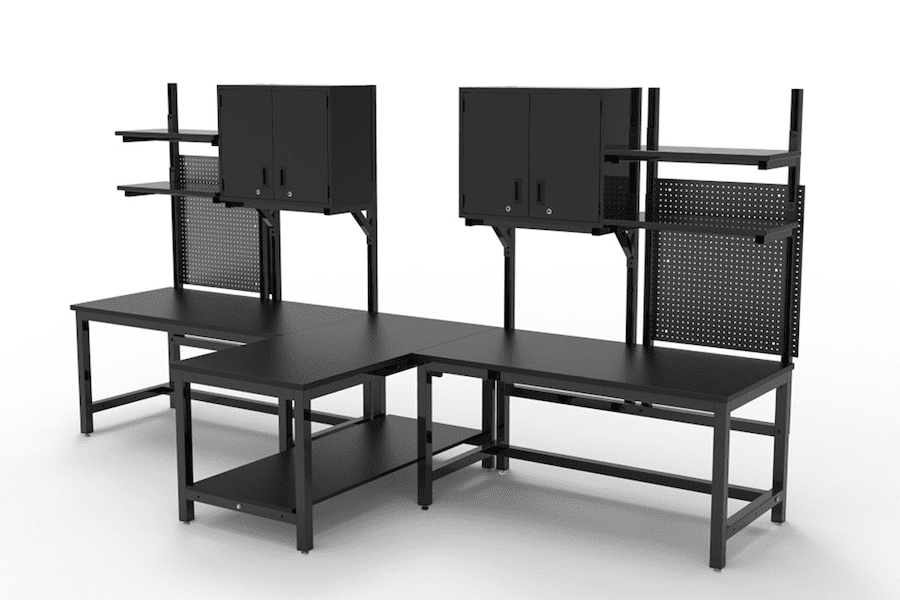

Personalized Workbenches

Custom-engineered configurations built around your assembly process, including bin rails, pegboards, monitor mounts, tool rails, and workflow-specific accessories.

Key Features of Electronics Assembly Workbenches

Electronics assembly workbenches must balance protection, access, and organization. These core features support quality, efficiency, and repeatable assembly output.

- ESD-Safe Surfaces & Grounding – Static-dissipative tops, grounding points, and ESD accessories protect components and assemblies from static damage.

- Versatile Storage & Parts Organization – Integrated bin rails, shelves, pegboards, and rack systems keep components and tools in easy reach.

- Monitor & Tool Mounting Systems – Adjustable monitor arms and tool mounts improve visibility and workflow efficiency on the assembly line.

- Integrated Power & Utilities – Electrical outlets, USB/data ports, and lighting support soldering stations, test equipment, and inspection tools.

- Ergonomic & Adjustable Workstations – Sit-stand options, keyboard trays, and adjustable shelves promote comfort and reduce strain.

- Modular Accessories & Expansion Options – Add drawers, cabinets, cable management, task lights, or tooling panels as your workflow evolves.

Typical Electronics Assembly Use Cases

ESD-Sensitive Assembly Lines

Workstations with static-dissipative surfaces and grounded accessories for PCB handling, component insertion, and connector assembly.

Soldering & Rework Stations

ESD-safe benches with integrated lighting, fume control options, and task-specific tool organization.

Inspection & Quality Control Workstations

Ergonomic benches with monitor mounts and precision lighting for inspection, AOI stations, and testing workflows.

Component Kitting & Parts Staging

Stations with bin rails, rack systems, and shelving to organize reels, trays, and small parts for streamlined assembly.

Functional Testing & Diagnostics Areas

Workbenches integrated with power, data ports, and test equipment mounting to support device testing and validation.

Packaging & Final Assembly Support Zones

Workstations near packing and final verification points to facilitate order fulfillment and quality checks.

Customization Options & Electronics Assembly Workbench FAQs

Electronics assembly environments require tailored workstations that balance static protection, organization, and ergonomic efficiency. These FAQs address common customization considerations.

- Do electronics assembly benches need ESD features?

Yes — most electronics assembly tasks involve ESD-sensitive components, so static-dissipative surfaces, grounding hardware, and ESD accessories are essential. - Can workbenches support bin rails, pegboards, and storage systems?

Absolutely — benches can be configured with integrated bin rails, pegboards, shelves, racks, and drawer systems for organized parts access. - Can these workstations integrate monitor mounts and utility connections?

Yes — workbenches can include adjustable monitor arms, electrical outlets, data ports, and lighting to support inspection and test equipment. - Are these benches suitable for both production and lab workflows?

Yes — modular designs support production line assembly, quality control stations, test areas, and light lab workflows. - Why choose Workbenches.com for electronics assembly workstations?

We understand ESD-critical environments, storage and organization needs, and precision assembly workflows — ensuring your benches are engineered for reliability and efficiency.

Ready to design an electronics assembly workstation tailored to your workflow?

How to Choose the Right Electronics Assembly Workbenches

Selecting the right electronics assembly workstation depends on your task requirements, static sensitivity, and workflow layout. Consider these key factors when configuring your bench.

- ESD Protection Needs – Assess component sensitivity and choose appropriate static-dissipative surfaces and grounding systems.

- Parts Storage & Access – Include bin rails, racks, pegboards, and shelves to keep critical components organized.

- Monitor & Utility Integration – Plan for monitor mounts, power, data connections, and lighting based on inspection and testing needs.

- Operator Ergonomics – Sit-stand options, adjustable shelves, and task lighting reduce fatigue and enhance precision.

- Modularity & Expansion – Modular systems allow you to add accessories or reconfigure layouts as production evolves.

- Space & Workflow Planning – Ensure bench footprints align with line flows, safety zones, and operator movement paths.