Manufacturing Workbenches

In demanding manufacturing environments, the right workbench isn’t optional—it’s essential. At Workbenches.com, we design and build industrial-grade workbenches engineered for strength, durability, and workflow efficiency. Whether you need heavy-duty benches to support machinery, ergonomic workstations to improve operator comfort, or modular solutions that evolve with production needs, we provide robust, customizable furniture tailored to meet the rigorous demands of modern manufacturing.

Contact our product specialists to configure a workbench that supports your production goals.

Manufacturing Workbenches: Built for Strength & Versatility

Explore our core product offerings designed to support pharmaceutical operations with durability, compliance, and flexibility:

Core Bench

A durable, general-purpose industrial workbench with 1,000 lbs capacity, customizable with accessories and storage options.

Upper Deck Workbench

Heavy-duty bench with integrated overhead shelving, ideal for assembly or packing stations needing vertical storage.

Utility Workbench

Robust bench with drawers, pegboards, and tool storage, perfect for maintenance, repair, or heavy-duty assembly tasks.

Personalized Workbenches

Fully custom-built benches tailored to unique production needs, processes, or specialized manufacturing applications

Modular Casework

Flexible, reconfigurable storage systems that adapt to evolving manufacturing workflows and equipment layouts.

Industrial Storage Racks

Adjustable shelving designed to hold heavy parts, tools, and materials securely within industrial spaces.

Types of Manufacturing Furniture: Built for Strength, Precision & Workflow Efficiency

Explore specialized furniture solutions designed to support assembly, fabrication, material handling, and production workflows in industrial environments.

Heavy-Duty Workbenches

- Reinforced frames – Support high loads, machinery, and equipment.

- Durable tops – Impact- and chemical-resistant surfaces.

- Built for longevity – Designed for harsh industrial environments.

Light-Duty Manufacturing Workbenches

- Cost-effective – For assembly or inspection requiring lighter loads.

- Compact footprint – Ideal for limited space applications.

- Customizable – Add shelving, pegboards, or drawers.

Assembly Line Tables

- Workflow-focused – Designed for repetitive assembly with bin rails or conveyors.

- Customizable tops – Optional cutouts or ball transfer inserts.

- Accessory-ready – Supports tool trolleys, lighting, or part bins.

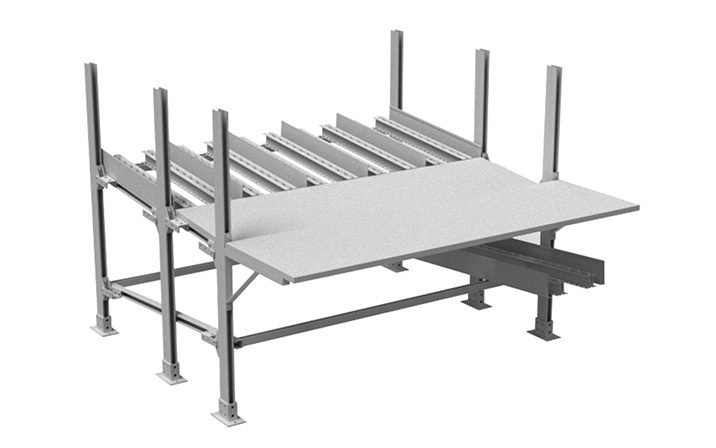

Conveyor-Integrated Workstations

- Seamless material flow – Built-in conveyors to connect workstations.

- Reduces manual handling – Moves products along the line automatically.

- Improves productivity – Supports continuous assembly or packaging processes.

Flow Racks

- Gravity-fed system – Supports FIFO material flow.

- Space-saving – Maximizes storage density at the line.

- Integrates with conveyors – Easy loading/unloading of components

Tool Storage Cabinets

- Secure locking – Protects valuable tools and parts inventory.

- Adjustable shelving – Fits tools of various sizes.

- Integrated drawers – Organizes frequently used supplies.

Material Handling Carts

- Heavy-duty casters – Easy transport of tools, parts, or components.

- Configurable – Add bins, shelving, or racks for organization.

- Mobile flexibility – Moves supplies across workstations efficiently.

Trends in Manufacturing Furniture Design: Evolving for Efficiency, Flexibility & Longevity

Explore emerging trends shaping manufacturing workspaces to improve productivity, worker safety, and adaptability for modern production needs.

- Lean Manufacturing Principles – Workbenches designed to support continuous improvement, minimize waste, and streamline workflows.

- Modular & Reconfigurable Layouts – Flexible setups that adapt to evolving production lines, reducing downtime for changeovers.

- Integration with Automation – Furniture built to interface with conveyor systems, robotics, sensors, and automated equipment.

- Ergonomic Design Focus – Height-adjustable benches and supportive accessories to reduce worker fatigue and repetitive strain.

- Durability & Industrial Longevity – Heavy-duty materials and reinforced structures designed for high-impact, long-term industrial use.

- Technology Integration – Integrated power outlets, monitor arms, and cable management to support digital tools and production monitoring.

Environments We Serve: Supporting Manufacturing from Floor to Finish

Aerospace Production Facilities

Heavy-duty benches for precision component assembly, inspection, and testing.

Automotive Manufacturing

Workstations for assembly, inspection, repair, and parts fabrication in automotive plants.

Medical Device Manufacturing

Specialized benches for assembling, testing, and packaging precision medical equipment.

Electronics Assembly Lines

Specialized workbenches supporting circuit board assembly and device manufacturing.

Defense & Military Production

Rugged workstations built for tactical equipment assembly and maintenance.

Maintenance & Repair Shops

Utility benches designed for equipment repair, tool maintenance, and part servicing.

Heavy Equipment Manufacturing

Durable benches supporting large component assembly and maintenance operations.

Metal Fabrication Shops

Workbenches for welding, cutting, grinding, and metal part assembly.

Customization Options: Tailored Solutions for Every Manufacturing Environment

Explore customization options to build a workbench system that aligns with your unique production, storage, and workflow requirements.

- Worksurface Choices – Select from stainless steel, phenolic, HDPE, hardwood, or laminate tops based on application needs.

- Storage Integration – Add drawers, shelves, pegboards, or cabinets for organized tool and material access.

- Accessory Add-Ons – Include bin rails, tool trolleys, louvered panels, or lighting for improved functionality.

- Conveyor System Integration – Customize workbenches to connect with conveyors for seamless material handling.

- Mobility Enhancements – Optional heavy-duty locking casters to move benches or equipment as needed.

- Personalized Configurations – Modify dimensions, weight capacities, or layouts to fit specific processes or facility constraints.

Contact our team to start designing a manufacturing workbench system tailored to your production goals and facility requirements.