Oil & Gas Workbenches

Oil and gas facilities demand workstations capable of performing in extreme conditions. From heavy mechanical maintenance to laboratory testing and field instrumentation, our oil & gas workbenches are engineered to deliver exceptional strength, durability, chemical resistance, and long-term modularity—supporting critical operations day after day.

Whether your team services drilling equipment, prepares field tools, or conducts compliance-driven laboratory analysis, our specialists can help you configure the ideal workstation for your environment.

Why Oil and Gas Workbenches Matter

Oil and gas operations span a broad mix of industrial and laboratory tasks — each requiring highly specialized workstation features such as reinforced frames, chemical-resistant surfaces, ESD options, and integrated utilities. Purpose-built oil & gas workbenches enhance:

- Operator safety during heavy-duty repair and inspection tasks

- Chemical compliance and cleanliness in petroleum, gas, and materials testing labs

- Workflow efficiency across maintenance, R&D, QC, and instrumentation

- Long-term durability in facilities exposed to corrosion, vibration, or high-frequency use

- Modularity and scalability as workflows evolve with new tooling or new testing methods

Recommended Oil & Gas Workbench Solutions: Built for Heavy-Duty Work, Lab Testing & Field-Ready Performance

Our workbench systems are designed to support upstream, midstream, and downstream operations, combining industrial strength with laboratory-grade functionality.

Services Lab Bench

Clean, utility-ready workbench designed for petroleum laboratories, sample analysis rooms, chemical testing, and quality control environments.

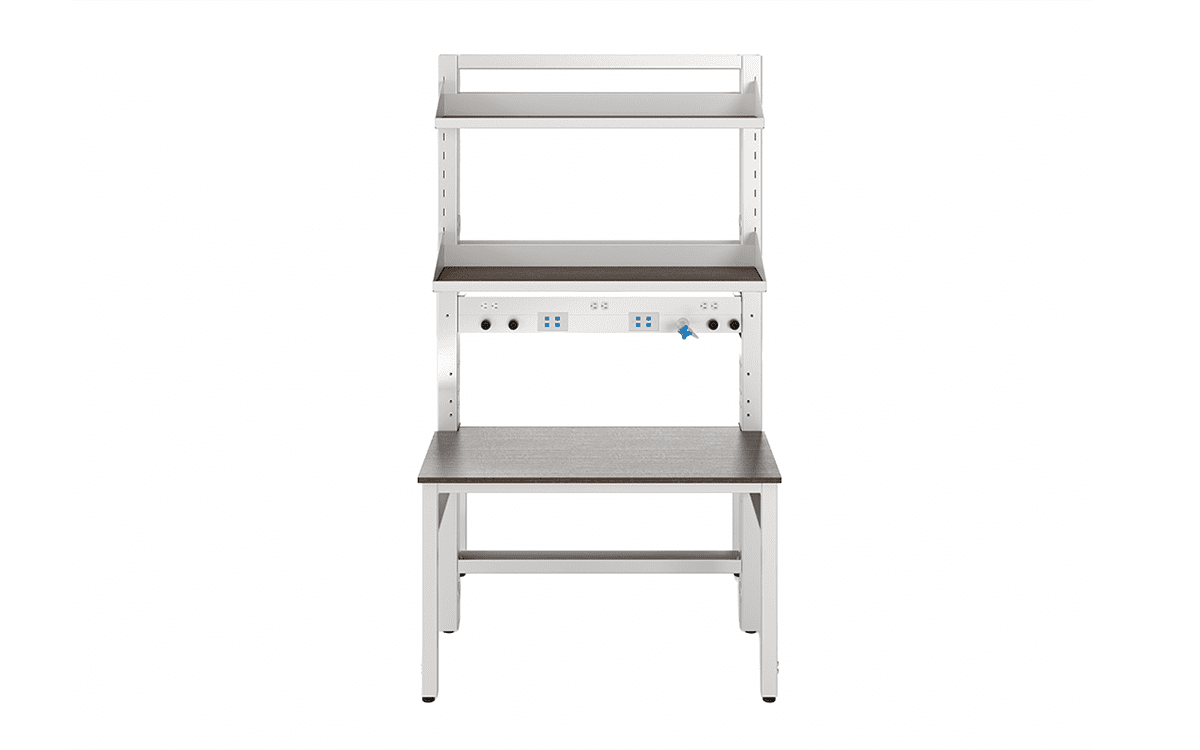

UpperDeck Workbench

Ergonomic workstation with overhead storage and integrated lighting, ideal for inspection tasks, electronics testing, and equipment preparation.

CoreBench

Modular industrial workbench suited for mechanical repairs, tool layout, and instrumentation setups in maintenance and field-service areas.

Utility Workbench

Heavy-duty platform built for drilling equipment servicing, valve maintenance, fabrication tasks, and rugged industrial operations.

Industrial Storage Racks

High-capacity storage solutions for tools, fittings, valves, PPE, and lab supplies—keeping maintenance bays and testing environments organized.

Personalized Workbenches

Fully customized configurations engineered for specialized testing methods, instrumentation layouts, hazardous materials workflows, or unique mechanical processes.

Key Features of Aerospace Workbenches

Oil and gas environments demand workbenches that withstand heavy loads, chemical exposure, and rigorous daily use. These core features ensure each workstation performs reliably in both industrial and laboratory settings.

- Heavy-Duty Frames & High Load Capacity – Reinforced steel construction supports large tools, drilling components, and heavy mechanical systems with long-term stability.

- Chemical-Resistant Worksurfaces – Epoxy, phenolic, stainless steel, or laminate tops withstand oils, solvents, fuels, and corrosive testing agents.

- Integrated Utilities & Power Options – Add power strips, gas connections, data ports, or specialized mounting features for lab equipment and instrumentation.

- Modular & Field-Ready Configurations – Adjustable shelving, drawers, tool storage, and accessory rails adapt to changing tasks and equipment needs.

- ESD-Safe Options for Sensitive Equipment – Ideal for handling sensors, electronics, metering devices, and communication tools used in field operations.

Typical Oil & Gas Use Cases

Drilling Equipment Maintenance & Mechanical

Repair Robust, vibration-stable workstations for servicing motors, pumps, valves, and heavy mechanical components.

Field Equipment Prep & Staging Areas

Modular stations designed for tool organization, pre-deployment checks, and component assembly for field crews.

Oil & Gas Laboratory Testing & QC

Chemical-resistant benches ideal for viscosity testing, elemental analysis, contamination checks, and hydrocarbon evaluation.

R&D & Engineering Applications

Flexible workbenches supporting prototyping, materials research, and innovation projects across upstream and downstream operations.

Instrumentation & Electronics Setup

ESD-safe work cells tailored for configuring sensors, telemetry devices, metering systems, and monitoring equipment.

Training & Simulation Environments

Durable stations for hands-on technical training, safety exercises, and equipment familiarization.

Customization Options & Oil and Gas Workbench FAQs

Oil and gas operations often require tailored workstations that match specific mechanical, laboratory, or instrumentation workflows. These FAQs highlight the customization options available for your environment.

- What worksurface materials are best for oil & gas applications? Epoxy, phenolic resin, stainless steel, and chemical-resistant laminates are ideal for environments exposed to fuels, solvents, and corrosive agents.

- Can these workbenches support heavy mechanical repair tasks? Yes — our heavy-duty frames are built to handle substantial loads and frequent use, making them suitable for drilling equipment, pumps, and industrial tooling.

- Do oil & gas labs require specialized bench configurations? Often yes — utilities such as gas service, power integration, fume hood compatibility, and spill-resistant surfaces are common requirements in energysector labs.

- Can workbenches integrate with tool storage or material-handling systems? Absolutely — benches can align with carts, racks, storage systems, and custom fixtures to streamline maintenance and testing workflows.

- Why choose Workbenches.com for oil & gas furniture? Our team has direct experience working with leading energy companies, giving us a deep understanding of both heavy-duty industrial and laboratory requirements unique to the oil & gas sector.

Ready to design a workbench built specifically for your oil & gas application?

How to Choose the Right Oil & Gas Workbenches

Selecting the right workstation depends on your operational environment, task requirements, and durability expectations. Here are the key factors to consider when configuring an oil & gas workbench:

- Load Capacity & Structural Strength – Ensure the frame and worksurface can support heavy tools, pumps, valves, and mechanical components used in maintenance tasks.

- Chemical Resistance – Choose epoxy, phenolic, laminate, or stainless steel surfaces for environments exposed to fuels, solvents, acids, and testing reagents.

- Utility & Power Integration – Determine whether you need gas service, electrical outlets, data ports, shelving, lighting, or equipment mounting solutions.

- ESD Requirements – If you work with sensors, electronics, meters, or instrumentation, ESD-safe configurations protect against static-related damage.

- Environmental Conditions – Consider vibration, temperature changes, humidity, and corrosive exposure in both industrial and lab environments.

- Modularity & Future Flexibility – A modular system allows you to adapt as workflows evolve, tools change, or teams expand.

- Space Planning & Workflow Optimization – Your bench should support efficient movement, tool access, and ergonomic safety for your specific processes.