Semiconductor Workbenches

Semiconductor facilities require highly controlled work environments where contamination control, electrostatic protection, and precision are critical to yield and reliability. Our semiconductor workbenches are engineered for cleanroom and cleanroom-adjacent applications, ESD-sensitive processes, and high-precision lab and support operations, delivering modular flexibility without compromising cleanliness or process integrity.

Need cleanroom-ready or ESD-safe workstations for semiconductor operations? Our specialists can help configure the right solution.

Why Semiconductor Workbenches Matter

Semiconductor manufacturing, packaging, and testing require extremely stable and contamination-resistant work surfaces that protect sensitive components and maintain process integrity. Purpose-built semiconductor workbenches enhance:

- Product cleanliness by minimizing particle shedding and human contamination

- ESD protection for circuits, wafers, sensors, and microelectronics

- Workflow accuracy through ergonomic, vibration-stable surfaces

- Process control in assembly, metrology, and inspection environments

- Modularity for rapidly evolving semiconductor tooling and layouts

- Operator safety and comfort during repetitive, high-precision tasks

Recommended Semiconductor Workbench Solutions: Built for Cleanroom Precision, ESD Safety & High-Tech Assembly

These Workbenches.com product lines align with the most common semiconductor applications, from cleanroom-adjacent assembly and labs to inspection, testing, and backend support areas.

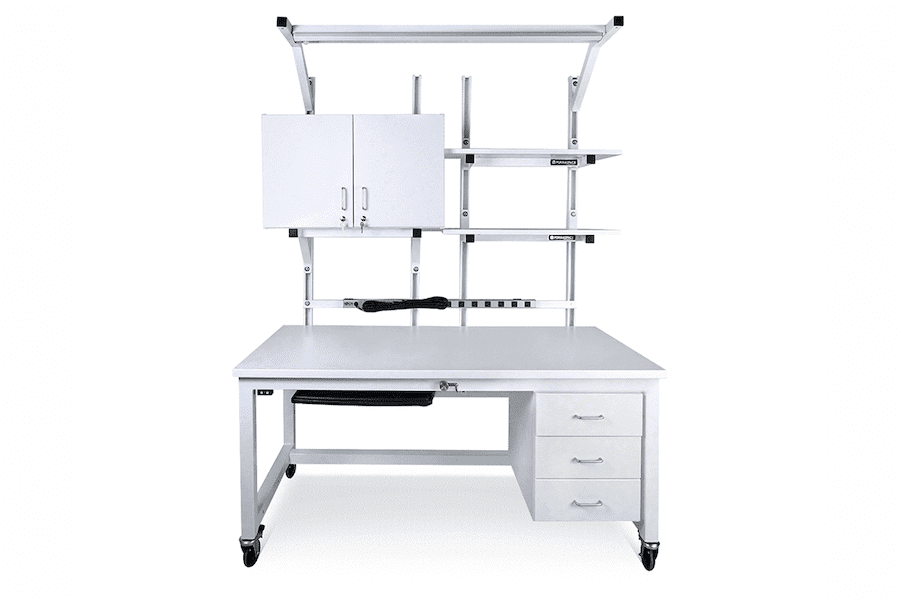

Services Lab Bench

Clean, utility-ready bench designed for semiconductor testing, diagnostics, failure analysis, and contamination-sensitive laboratory environments.

UpperDeck Workbench

Ergonomic workstation with overhead lighting and accessory support — well-suited for inspection, microscopy, metrology tools, and precision electronics work.

CoreBench

Modular workbench platform ideal for ESD-controlled assembly, subassembly, wafer-handling support tasks, and cleanroom-adjacent tech lab workflows.

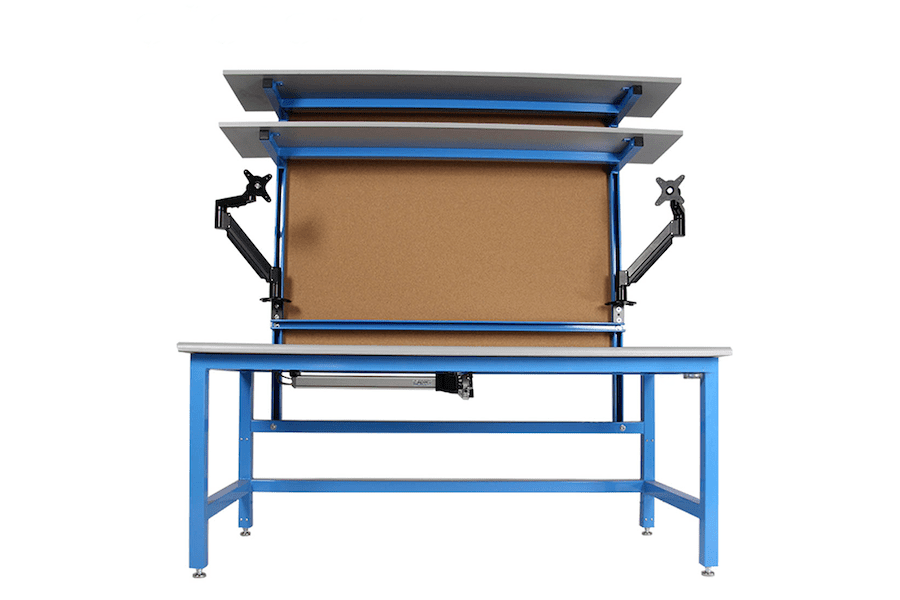

Height - Adjustable Desks

Sit-stand workstations designed for precision tasks, inspection work, and prolonged semiconductor assembly where ergonomics and focus are critical.

Industrial Storage Racks

Cleanroom-compatible or powder-coated storage solutions for tooling, carriers, consumables, and documentation in cleanroom-adjacent support zones and backend operations.

Personalized Workbenches

Custom-engineered configurations for wafer handling stations, ESD-critical assembly, integrated equipment layouts, and specialized semiconductor processes.

Key Features of Semiconductor Workbenches

Semiconductor environments demand workbenches designed around cleanliness, static control, and precision. These features ensure reliable performance across cleanrooms, labs, and support areas.

- Cleanroom-Compatible Construction–Low-shedding materials, smooth surfaces, and powder-coated or stainless-steel frames suitable for controlled environments.

- ESD-Safe Worksurfaces–Static-dissipative laminates and grounding options protect wafers, chips, PCBs, and sensitive microelectronics.

- Precision & Stability–Rigid frames and vibration-resistant surfaces support microscopy, metrology, and inspection tasks.

- Integrated Power & Utilities–Electrical outlets, data ports, lighting, and equipment mounting options support semiconductor tools and lab instruments.

- Modular Accessories & Storage–Shelving, monitor arms, tool rails, and drawers keep work zones organized while maintaining contamination control.

- Ergonomic Adjustability–Height-adjustable options reduce fatigue during long-duration assembly, inspection,and analysis tasks.

Typical Semiconductor Use Cases

Cleanroom - Adjacent Assembly & Wafer Handling Support

Low - shedding, ESD - safe workstations for wafer prep support tasks and controlled assembly outside core fab automation zones.

ESD - Safe Electronics & Package Assembly

Static - controlled benches for chip packaging, PCB integration, and sensitive electronics work.

Metrology & Inspection Workstations

Ergonomic, vibration - stable benches designed for microscopy, measurement tools, and precision inspection.

Semiconductor Lab Testing & Failure Analysis

Chemical - resistant benches supporting diagnostics, material analysis, and R&D labs.

Equipment Setup & Calibration Areas

Stable work surfaces for configuring sensors, test equipment, and instrumentation.

Backend Operations & Support Zones

Workstations and storage supporting test, packaging, documentation, and controlled material staging outside core cleanroom spaces.

Customization Options & Semiconductor Workbench FAQs

Semiconductor workflows often require highly specialized workstation configurations to meet strict cleanliness, static control, and precision standards. These FAQs outline common customization considerations.

- Can semiconductor workbenches be cleanroom-rated?

Yes—workbenches can be configured with low-shedding materials, smoothsurfaces, and cleanroom-compatible components for controlled environments. - Do semiconductor applications require ESD-safe options?

In most cases, yes. ESD-safe worksurfaces and grounding systems are criticalfor protecting wafers, chips, and sensitive electronics. - Can workbenches integrate with microscopes and testing equipment?

Absolutely—benches can be customized with reinforced surfaces, cut-outs, power integration, and mounting options for precision tools. - Are storage and staging solutions used in semiconductor facilities?

Yes—cleanroom-adjacent support zones and backend operations rely oncontrolled storage for tooling, consumables, and documentation. - Why choose Workbenches.com for semiconductor workstations?

Our team understands cleanroom environments, ESD-critical processes, andsemiconductor workflows—allowing us to design workstations that perform reliably from day one.

Ready to design a cleanroom - ready or ESD - safe workstation for semiconductor operations?

How to Choose the Right Semiconductor Workbenches

Choosing the right semiconductor workstation depends on cleanliness requirements, component sensitivity, and workflow precision. These considerations help guide the right configuration.

- Cleanroom Compatibility – Match materials and finishes to ISO cleanroom classifications and contaminationcontrol standards.

- ESD Requirements – Select appropriate static-dissipative surfaces and grounding based on component sensitivity.

- Precision & Stability Needs – Ensure vibration resistance for inspection, microscopy, and metrology tasks.

- Chemical Resistance – Labs and analysis areas may require epoxy, phenolic, or stainless-steel surfaces.

- Accessory & Equipment Integration – Plan for lighting, power, monitors, shelves, and tool mounting.

- Scalability & Modularity – Modular systems allow fast adaptation as semiconductor processes evolve.