Testing Lab Workbenches

Testing laboratories — whether focused on materials analysis, environmental quality, industrial product certification, or chemical and biological assays — require workstations that support precision testing, controlled workflows, and reliable utility access. Our testing lab workbenches are engineered for chemical resistance, structural strength, ergonomic workflow, and customization, helping labs optimize accuracy, safety, and efficiency.

Need a testing lab workstation tailored to your testing protocols and space? Our specialists can help configure the ideal solution.

Why Testing Lab Workbenches Matter

Testing labs are held to high standards of quality, repeatability, and safety. Whether you’re evaluating materials, certifying products, analyzing environmental samples, or running QA processes, purpose-built testing workbenches help:

- Provide stable, vibration-resistant surfaces for sensitive instruments

- Support chemical handling and sample prep with resistant finishes

- Enable organized workflows with smart utility and storage solutions

- Reduce contamination and operator fatigue with ergonomic design

- Allow custom configurations tailored to unique testing methods and equipment layouts

Recommended Testing Lab Workbench Solutions: Built for Accuracy, Durability & Specialized Labwork

These Workbenches.com solutions support electronics assembly, testing, inspection, and kitting workflows. ESD-safe configurations are available where static control is required.

Services Lab Bench

Utility-ready lab bench designed for chemical testing, analytical workflows, QA/QC procedures, and controlled lab environments.

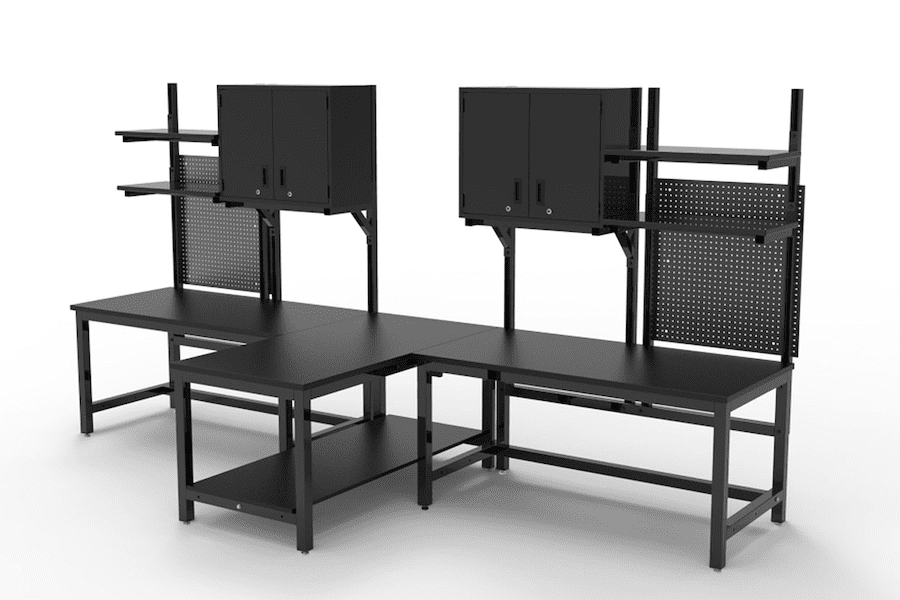

UpperDeck Workbench

Ergonomic workstation with overhead storage and lighting — perfect for testing stations, multi-step QA processes, and precision measurement areas.

CoreBench

Modular workbench platform ideal for sample prep, measurement support, and testing workflows that require adaptable layout and accessory integration.

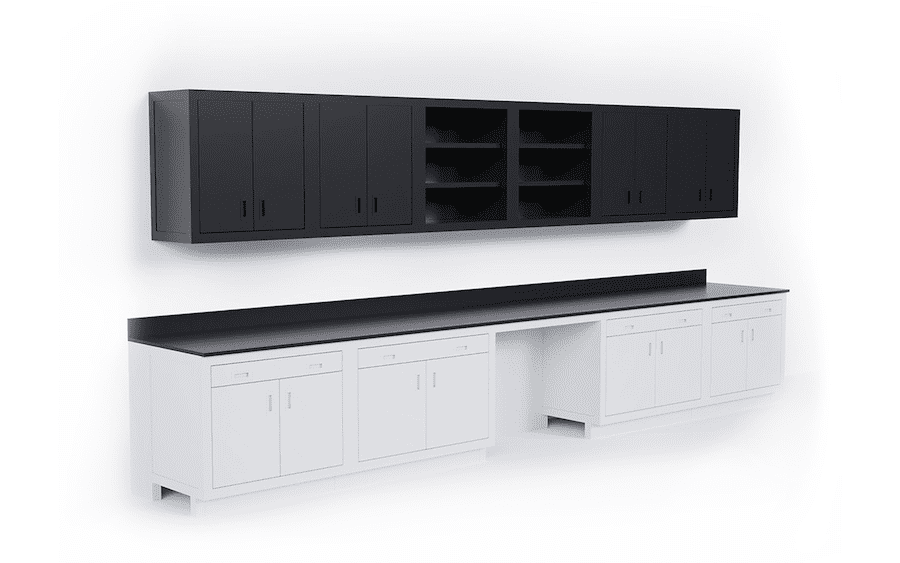

Modular Casework

Reconfigurable lab casework that keeps testing supplies, documentation, instruments, and consumables organized and accessible.

Lab Carts

Mobile carts configured for transporting samples, instruments, and supplies between testing stations and lab zones.

Personalized Workbenches

Custom configurations engineered around test protocols, instrument footprints, and utility needs.

Key Features of Testing Lab Workbenches

Testing laboratories require workstations designed for durability, utility integration, and workflow precision. These features help ensure consistent, reliable testing performance.

- Chemical-Resistant & Cleanable Surfaces – Phenolic, epoxy, stainless-steel, and other resistant tops withstand corrosive reagents and cleaning protocols.

- Integrated Utilities & Power Access – Electrical, gas, vacuum, data lines, task lighting, and power rails support instruments and testing equipment.

- Ergonomic & Adjustable Designs – Height adjustability, sit-stand compatibility, and thoughtful layout help reduce fatigue during repetitive testing tasks.

- Modular Accessories & Storage – Shelving, drawers, tool rails, and overhead storage keep tools, consumables, and documentation organized.

- Support for Specialized Equipment – Workstations can be configured to support test instruments like spectrometers, chromatographs, balances, and microscopy stations.

- Compliance & Safety Standards – Built to meet SEFA, EN 13150, or other lab safety and performance benchmarks where applicable.

Typical Testing Lab Use Cases

Sample Preparation Areas

Benches with chemical-resistant surfaces ideal for handling, labeling, and conditioning samples before analysis.

Analytical Instrument Stations

Workstations designed for chromatography, spectroscopy, microscopy, and other precision instruments with integrated utilities.

Quality Assurance & Validation Labs

Ergonomic benches supporting QA testing protocols, documentation review, and method verification in controlled settings.

Environmental & Materials Testing Zones

Workstations configured to handle environmental samples, material wear tests, stress analysis, and corrosion evaluations.

Calibration & Metrology Areas

Stable, vibration-resistant benches supporting measurement standards, instrument calibration, and metrology workflows.

Back-End Testing Support Space

Workstations located in support zones for equipment staging, supplies organization, and post-test processing.

Customization Options & Testing Lab Workbench FAQs

Testing labs often require tailored workstation configurations to support unique protocols, instruments, and safety requirements. These FAQs address common customization questions.

- What work surface materials are best for testing labs?

Epoxy, phenolic resin, and stainless-steel surfaces are common for chemical resistance, durability, and ease of cleaning. - Can workbenches integrate utilities like power, data, and gas?

Yes — benches can be configured with integrated electrical outlets, data ports, lighting, and utility access to support lab instruments. - Are mobile solutions used in testing labs?

Absolutely — lab carts and mobile workstations help transport samples, equipment, and supplies between zones. - Can testing lab workbenches be customized for specific instruments?

Yes — we can design benches with custom cut-outs, mounting points, and utility connections for your specific methods and devices. - Why choose Workbenches.com for testing lab workstations?

We understand the diverse needs of modern testing labs and engineer workstations that balance durability, utility integration, and workflow efficiency.

Ready to design a testing lab workstation tailored to your protocols?

How to Choose the Right Testing Lab Workbenches

Selecting the right testing lab workstation depends on your test methods, instrument types, and required utilities. Consider these key factors when configuring your bench.

- Surface Material & Chemical Compatibility – Choose surfaces based on the reagents, solvents, and cleaning protocols used in your lab.

- Utility Integration Needs – Ensure your bench provides adequate power, data, lighting, gas, and vacuum access for instruments.

- Ergonomics & Adjustability – Height adjustments, ergonomic platforms, and task lighting help reduce fatigue during repetitive tasks.

- Organization & Storage – Plan shelving, drawers, and casework to support orderly workflows and reduce clutter.

- Equipment Footprint & Workflow Flow – Configure benches around instrument footprints and procedural flows to maximize efficiency.

- Compliance & Standards – Consider standards such as SEFA and EN 13150 for performance, safety, and durability qualifications.